Metering Pumps are small, positive displacement pumps. Metering Pumps are designed to accurately pump a precise flow rate of chemicals or substances into a stream of water, steam, or gas. Metering Pumps are typically compact and powered by small electric motors or pneumatic drive units. Depending on the brand and type of pump, Metering Pumps operate using various methods. All these methods involve measuring a quantity of chemical and then pumping that product into a pipeline or similar vessel.

There are generally 4 different types of Metering Pumps, each with different mechanisms and adjustable settings to suit various applications, pressures, and different chemicals.

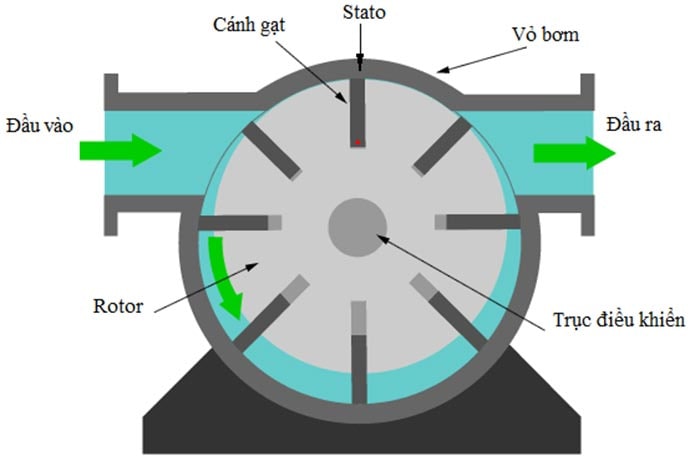

1. Rotary Vane Pumps

Rotary vane pumps are commonly used in industrial applications such as oil pumping, grease pumping, adhesive pumping, paint pumping, and other high-viscosity liquids. The advantages of rotary vane pumps include the ability to pump highly viscous liquids and operate smoothly with low noise.

Applications of Rotary Vane Pumps

Rotary vane pumps have various applications, apart from their main applications in the pharmaceutical and food industries, they also have specific applications in other areas of life. Rotary vane pumps are used in most clean industries with moderately viscous fluids.

- Food industry: Rotary vane pumps are used to pump tomato sauce, ketchup, pudding, candies, food-grade oil, minced meat, sugarcane juice, honey, syrup, chocolate, and more.

- Chemical industries: They are used for pumping grease, solvents, plant resins, dyeing materials, and more.

- Application in beer, wine, and soft drink industries.

- Application in butter, milk, yogurt, and cheese industries.

- Application in the pharmaceutical industry.

- Pumping of thick paints, adhesives, and inks.

- Application in the animal feed industry for pumping honeycomb and fish oil.

- Pumping of rubber, chocolate, asphalt, and hot tar.

- Cosmetics industry, heavy industry, mining, and more.

- Other industries and fields……

2. Reciprocating Piston Pump

In the case of a pump chamber filled and emptied by a piston and a diaphragm with valves on the inlet and outlet. When the chamber is filled by drawing in the piston, then depending on the metered amount (generally as a percentage of the maximum flow rate), a measured volume is pumped out at a certain rate. These pumps are highly accurate and provide a nearly constant flow rate ranging from 6-250L/hour. With precise control, they can also deliver variable dosing rates.

3. Diaphragm Metering Pump

This is where the diaphragm barrier mechanism comes into play again, but instead of a slow and continuous flow rate, the pump is controlled by an electromagnetic coil. These coils draw in and pump chemicals in pulses, with a time interval between pulses providing flow rate control. This makes this type of pump much less precise as the product is dispensed in pulses with a time interval between injections. They are typically very simple in terms of mechanics and electronics, and also inexpensive.

Below are some key applications of diaphragm metering pumps:

- Chemical industry: Diaphragm metering pumps are widely used in the chemical industry to supply fluids from storage tanks to production processes. They can pump corrosive, flammable, volatile, and hazardous liquids.

- Water and wastewater treatment: Diaphragm metering pumps are used for water and wastewater treatment in applications such as drinking water treatment, industrial wastewater treatment, and pool water treatment. They can handle liquids containing chemicals and solids.

- Food and beverage industry: Diaphragm metering pumps are used in the food and beverage industry to pump liquids such as water, fruit juice, sugar, beer, wine, and other ingredients in the production process.

- Oil and gas industry: Diaphragm metering pumps are used in the oil and gas industry to pump liquids such as gasoline, diesel, crude oil, and chemical mixtures in the exploration, transportation, and processing of oil and gas.

- Chemical processing: Diaphragm metering pumps are used to pump chemical liquids in processing processes such as pesticide spraying, pool water treatment, and other industrial processes.

4. Peristaltic Pump

The peristaltic pump, also known as a hose pump, is a specialized and highly accurate metering method. It operates by having a flexible tube through which the product must pass. These tubes are bent in a crescent shape, and a small roller on a mechanical arm moves outward on the tube. This action then captures a portion of the product within the tube and pushes it along and into the metering and main flow tubes. These pumps are widely used in the medical industry because they are easily sterilized, and the pumping mechanism can quickly be changed out if it becomes contaminated or damaged.

If there are issues at the product level or similar, sometimes there are activated warnings to alert the operator, and if the product runs out, the system can also shut down or provide higher alarms to prevent untreated water or liquid from causing further incidents.

Below are some common applications of peristaltic pumps:

- Well water pumping: Peristaltic pumps can be used to pump water from wells or deep groundwater sources. When placed in a well, the pump creates pressure and moves the water to the surface for purposes such as household water supply or irrigation.

- Pool water pumping: Peristaltic pumps are used in water treatment and filtration systems for swimming pools. The pump takes water from the pool, passes it through a filter to remove debris, and returns clean water back to the pool. This helps maintain water quality in the pool.

- Automatic irrigation system: Peristaltic pumps can be used in automatic irrigation systems. The pump takes water from a water source such as a well or reservoir and pushes water through pipes to irrigate plants in a garden or area.

- Chemical pumping: In industrial processes or water treatment, peristaltic pumps can be used to transfer chemicals from storage tanks to processing or reaction equipment.

- Firefighting pump systems: Peristaltic pumps are used in firefighting pump systems to provide pressure and move water from a water supply source to spray nozzles for extinguishing fires.

As a function, a metering pump is designed to be reliable, so once it is set up correctly, it will take care of itself and not require a large amount of input. Viet Thai TT Trading and Service Co., Ltd. is the exclusive distributor of EMEC products in Ho Chi Minh City. In addition to Metering Pumps, we also have other outstanding products such as metering pumps, disinfection systems, water metering transmitters, sensors, chemical pumps, submersible wastewater pumps, and more.

– Our products serve the manufacturing and environmental sectors.

– We specialize in supplying chemical measurement equipment such as chemical metering pumps, measuring devices like pH meters, conductivity meters, chemical storage tanks, etc.

– Our customers include multinational companies and factories such as Coca-Cola, Pepsi, Unilever, P&G, Colgate, Pamolive, Lavie, Nestle, Heineken, as well as industrial zones.

– We not only supply equipment but also provide installation support upon request.

– Furthermore, we offer free and attentive customer support to address any inquiries.

We commit to selling 100% genuine complete sets. When purchasing products from VIET THAI T.T CO., LTD you will receive a 12-month warranty and a 1-for-1 exchange policy within the first 3 days from the date of purchase. Therefore, if you have a need to purchase chemical metering pumps, please contact us:

VIET THAI T.T CO., LTD

Address: 2/6 Nguyen Huy Luong, Ward 14, Binh Thanh District, Ho Chi Minh City

Phone: (+84-28) 35511793 – Fax: (+84-28) 35511794

Email: info@vietthaiaqua.com

Website: vietthaiaqua.com